Geogrids for walls and slopes: do you know how to choose it?

There are number of different products, materials, and connections making up todays geogrid market. But do you know which geogrid suits your project best? Tailor Engineering will be able to help you.

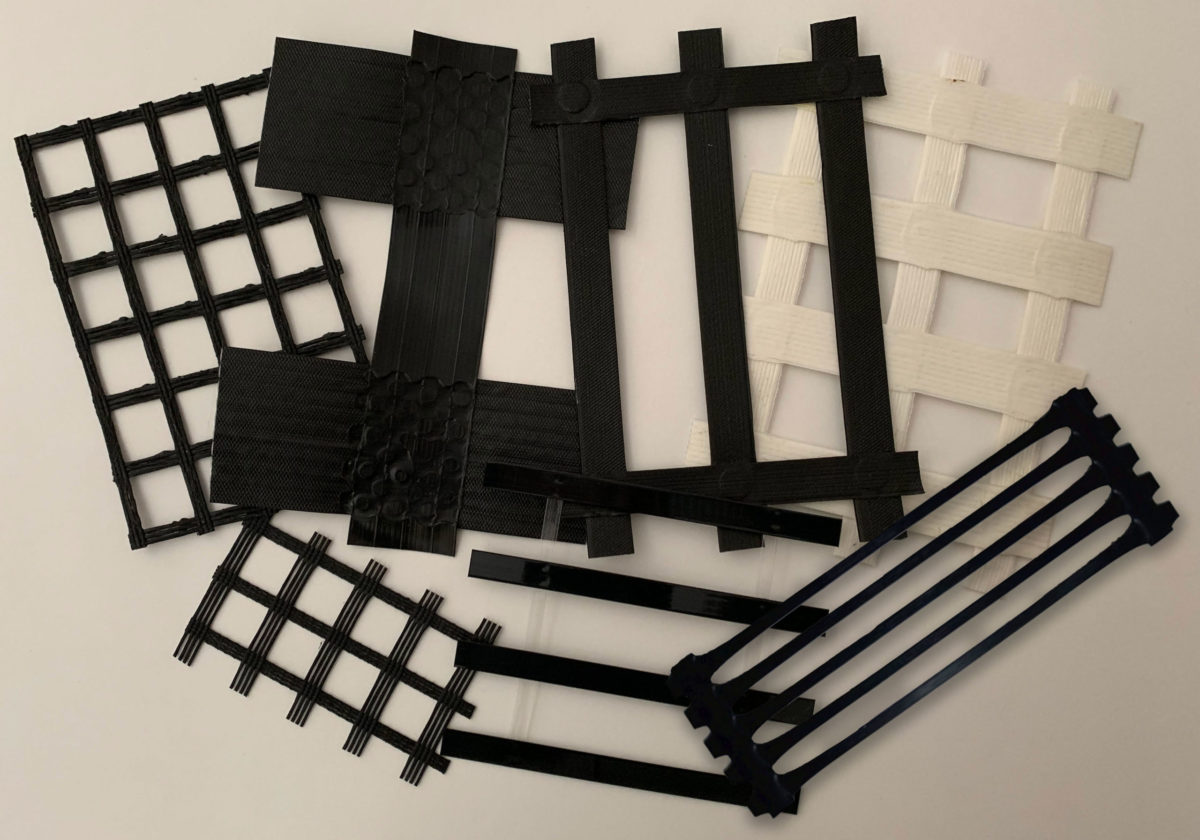

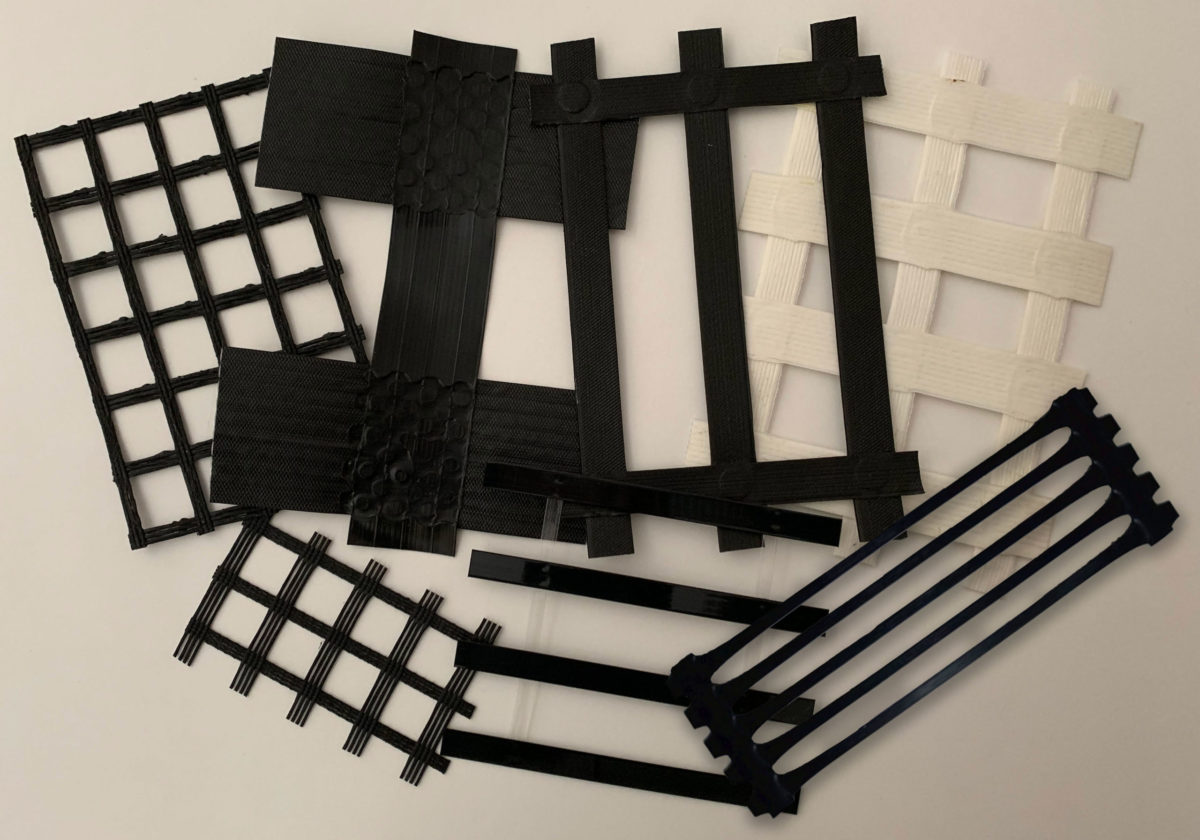

Geogrid is a planar, polymeric product consisting of mesh or net-like regular open network of intersecting tensile-resistant elements, called the ribs, integrally connected at the junctions. The ribs can be linked by extrusion, bonding or interlacing; the resulting geogrids are called extruded geogrids, bonded geogrids and woven or knitted geogrids, respectively. Geogrids for reinforcement application are made with a variety of polymeric material such as HDPE, polyester (PET), polypropylene (PP) and other resins such as PVA.

Extruded geogrids using HDPE, were first made in the United Kingdom by Netlon Ltd (now Tensar) in the mid-70s, followed by the Italian Tenax. More flexible, textile geogrids using bundle of polypropylene coated polyester fibers as the reinforcing component were used from 1977 by ICI in Yorkshire, UK (now Linear Composites). Those geogrids are manufactured by bonding the mutually perpendicular PET strips together at their crossover points using either laser or ultrasonic welding. Polypropylene (PP) roads or straps can also be bond in a grid-like pattern; for example, Colbond/Bonar and Naue manufacture this type of geogrids.

Woven and knitted geogrids are manufactured by weaving or knitting process from polymer multi-filaments. Although PET yarns are by far the most widely used, fiberglass, nylon and PVA yarns are also possible. In this process hundreds of continuous polymer fibers are gathered together to form yarns that are woven into longitudinal and transverse ribs with large open spaces between. The crossovers are joined by knitting or intertwining before the entire unit is protected by a subsequent coating. The geogrid coating varies between acrylic, EVA, PVC, SBR or bitumen to provide added protection against environmental attack and construction induced-damages. As the manufacturing technology is relatively flexible and quick with respect to others, there are possibly as many as thirty companies manufacturing coated yarn-type geogrids on a worldwide basis, from European based companies (such as Huesker, Alpe Adria Textil or Tencate) to Far East based companies such Strata (India), ACE (Taiwan) or Hock Technology (China), to name a few.

In the reinforcement application where the direction of the major stresses are known, as in walls and slopes, unidirectional (or uniaxial), geogrids are usually used. If the applied stresses come from random directions, bidirectional (or biaxial) geogrids are preferred. The design of reinforced soil slopes and walls involves considering the internal stability of the reinforced soil mass to determine the geometric arrangement of the geogrids and the tensile strength required to maintain stability. The overall stability of the reinforced soil block is also considered to ensure that failure by sliding, overturning, foundation bearing capacity, and along deep seated surfaces is avoided.

A geogrid must be selected on its certified performances and its specification may include: short term tensile strength; long term or creep limited tensile strength; strain at design stress; pull out resistance; interaction or friction coefficients between fill and geogrids; connection strengths when connected to facing systems such as blocks or gabions; installation damage resistance (damage during soil compaction); durability considerations o UV resistance for geogrids exposed on wrap around facings; chemical resistance for contact with soil or backfill materials, especially if demolition or recycled materials are used as fill (e.g PFA or crushed concrete).

- IMAGES:

- Netlon MSE wall in 1980 at Newmarket Silkstone Colliery, Yorkshire, UK (courtesy of Tensar)

- Linear Composites factory in Yorkshire producing geogrids since mid 70s (courtesy of LCL)

- Eroded steep slope protected by a toe geosynthetics reinforced green slope in Trento, Italy (courtesy of Huesker)

- Slopes and walls for the new M49 Junction, south of Bristol, UK (courtesy of Highway England)

- High load bearing wall to support 100-ton trucks built with blocks and geogrid in PA, USA (courtesy of Anchor Wall System)

- Earth dam reinforced with high strength geogrids used against seismic actions in China (courtesy of Hock Technology)